Tel-Valves

Telescoping Valves (Tel-Valves) are a simple and effective solution to regulate liquid levels, control flow, flow slitting, and decant operations in wastewater treatment operations.

Tel-Valves have no mechanical or wear items, which minimises operations and maintenance (O&M) costs, allows for installation and operational simplicity, and promotes long service life.

Contact an ExpertTel-Valves are a simple and effective solution for liquid regulation in wastewater treatment operations. Easy to install and operate, they have no mechanical or wear items, which minimises maintenance and lowers operations and maintenance costs. Tel-Valves have a long service life, capable of lasting up to 20 years, which is the typical life of a wastewater treatment plant. They are also customizable, with options such as flared skimming weirs or V-notch openings, and are available in a wide range of sizes from 101 to 406 mm (4 to 16 inches) to accommodate different pipe sizes and flow rates.

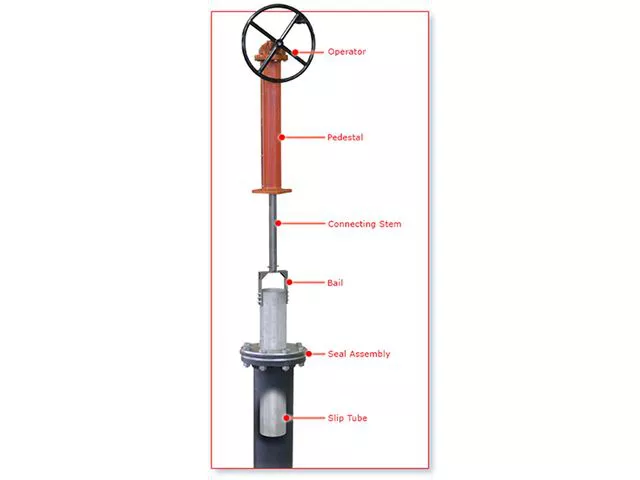

Tel-Valves consist of a slip tube, seal flange assembly, and receiving tube. The slip tube is raised and lowered by either a manual hand wheel or an automatic operator, such as pneumatic, electric, or hydraulic. The slip tube is typically made of a lightweight stainless steel. The top can have a plain circular opening or be customised with features such as a flared skimming weir or V-notch opening, depending on the application. The seal flange retains a ring of woven Teflon packing and acts to seal the gap between the slip tube and the receiving tube, which allows the slip tube to easily slide up and down within the larger tube.

To use the Tel-Valve, an operator simply turns the hand wheel or activates the automatic operator to raise or lower the slip tube to the desired position. This will either allow liquid to flow through the Tel-Valve or block the flow, depending on the desired level or flow rate.