G-TAD™ Process

The Gravity Thickened Aerobic Digestion (G-TAD) process is a controlled aerobic process meeting Class B stabilisation requirements and making use of a unique non-clog single drop diffuser system.

Requiring minimal operator supervision, the G-TAD process thickens solids up to 2 percent which can reduce aerobic digestion volume, footprint and energy costs.

Contact an ExpertWith 16,000 facilities treating more than 30 billion gallons of wastewater every day in the United States, biosolids management is a serious issue in municipal wastewater treatment and is responsible for between 30 and 60 percent of operating and maintenance expenses.

Ovivo’s G-TAD process solution is ideal for both new plants and existing plants looking to retrofit. These solutions also allow plants to maintain the industry standard of using solids in land applications instead of just disposing to landfills.

Improve biosolids management system with minimal cost and effort

Ovivo’s G-TAD process combine sludge thickening and controlled aerobic digestion into one seamless operation, dramatically improving your plants treatment ability to efficiently manage biosolids while reducing daily operating and maintenance costs. The features and benefits of these solutions include:

- Class B biosolids stabilisation

- Minimised footprint

- Operating simplicity

- Easy retrofit technology

- Minimal nutrients returned to the upstream liquid treatment process

- Reduced operating and disposal costs

- Minimal operator supervision during thickening

Downloadable Resources

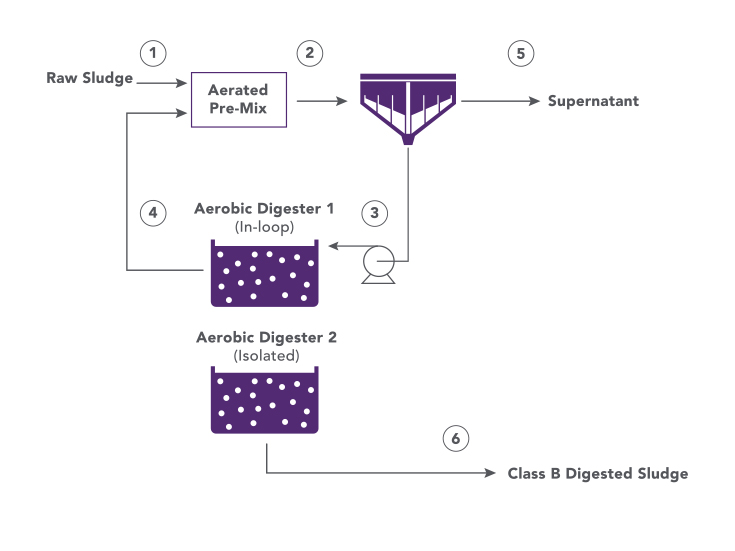

The G-TAD is a process that uses two aerobic digester basins along with a pre-mix basin and a gravity thickener to treat raw sludge. The raw sludge enters the premix basin where it is mixed and aerated to increase microbial activity and dissolved oxygen concentration. The sludge then overflows to the gravity thickener where solids settle to the bottom without aeration, creating an anoxic stage for denitrification to occur, stabilising the pH. The supernatant is removed and returned to the head of the plant. The thickened sludge is airlifted to the in-loop digester where nitrification occurs with less aeration than normally required due to alternating anoxic/aerobic phases. Scum is collected in the gravity thickener and also airlifted to the in-loop digester. Digested sludge overflows back to the pre-mix, completing the loop and continuously decanting and thickening the sludge.

1. Raw sludge and scum from liquid treatment process

2. Gravity Thickener Influent

3. Thickened Sludge and Scum airlifted from Gravity Thickener

4. Nitrified Sludge gravity flowing from In-loop Aerobic Digester

5. Gravity Thickener Supernatant

6. Class B Digested Sludge Product