TransMAX & MS Diffusers

TransMAX & MS Diffusers are versatile non-clog aeration systems for wastewater treatment and biosolids management. They provide excellent mixing and aeration of biosolids with simplified maintenance, long service life, and can handle high solid concentrations.

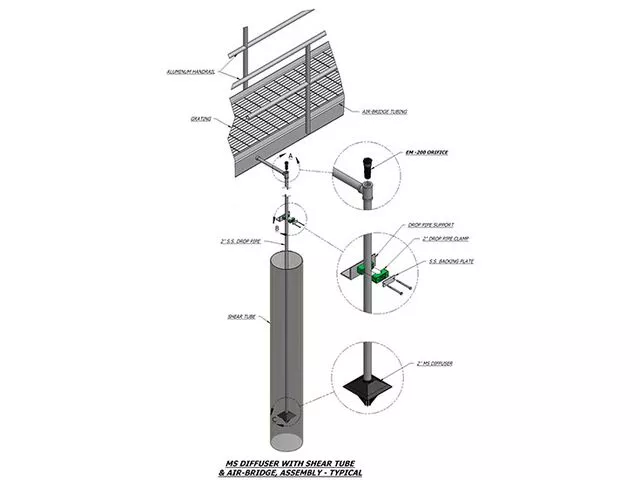

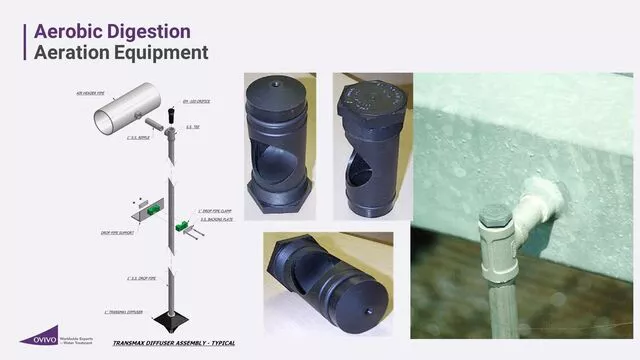

They can be used in various applications such as aeration basins, aerobic digestion, and channel aeration. Designed as a single drop diffuser and an above-water orifice, they eliminate the need for cleaning, even if the air is turned off.

Contact an ExpertThe TransMax and MS Diffusers are versatile systems that can be used in various applications, such as aeration basins, aerobic digestion, channel aeration, and EQ basins for wastewater or biosolids management. They can be applied to different types of tank geometries, whether it is a retrofit or new tank construction.

Since 1968, over one thousand TransMAX and MS diffusers have been installed for biosolids management and wastewater applications. These aeration systems have demonstrated their simplified maintenance over time. They have a long service life and provide outstanding aeration and mixing of biosolids up 3 percent concentration.

TransMAX and MS diffusers have many operational advantages over conventional diffuser systems, such as:

- Simplified diffuser maintenance that doesn’t require going inside, draining, or taking tanks out of service since the orifice assembly is accessible above the water surface

- No moving parts

- Non clogging orifice eliminates the need for redundant diffusers allowing sustainable and reliable performance

- Airflow is uninhibited through the entire length of the pipe

- Ability to cycle the air on and off without plugging or fouling the diffusers

- Long service life (20 years and above)

- Blowers operate the same discharge pressure over the life of the equipment ensuring uniform air distribution of biosolods

- Diffuser achieves medium bubble oxygen transfer rates of up to 14 percent

TransMAX and MS diffusers work by transferring air into the wastewater treatment basins.

The diffusers have a special design that separates the air metering orifice from the diffuser and locates it above the liquid level in the basin. This eliminates clogging, which is a common problem with traditional diffusers for biosolids management. No liquids or solids are ever in contact with the orifice, making it accessible for diffuser maintenance.

The airflow is completely uninhibited through the complete length of the drop pipe with no mechanical devices or swivel joints required to service the orifice.

This guarantees sustainable and reliable performance, and also eliminates the need for cleaning, even if the air is turned off for biosolids management. Since the air metering orifices are located above water level and can be accessed without draining the tank if the system is to be cleaned or altered.

In the video, you’ll see how the diffusers establish a clear roll pattern throughout the basin, ensuring that the contents in the reactor are well mixed. This helps to maintain consistent levels of dissolved oxygen, which is critical for effective wastewater treatment.