Ion exchange Water Filtration

Ion Exchange is used in plants around the world to produce high purity demineralised water for industrial processes. The system is economical and suitable for a wide range of applications.

Our engineers work closely with all our partners to ensure the correct Ion Exchange resins and processes are used to meet the specific needs of their process and provide the required demineralised water, specifically in cases of lower conductivity feed water or high raw water/disposal costs.

Contact an ExpertIon Exchange is a leading technology for removing dissolved minerals from water in a variety of industrial applications. Ovivo provides proprietary, sustainable solutions that are water and chemical efficient, designed to reduce operating costs and suitable for producing high purity demineralised water.

Flexible Ion Exchange Solutions

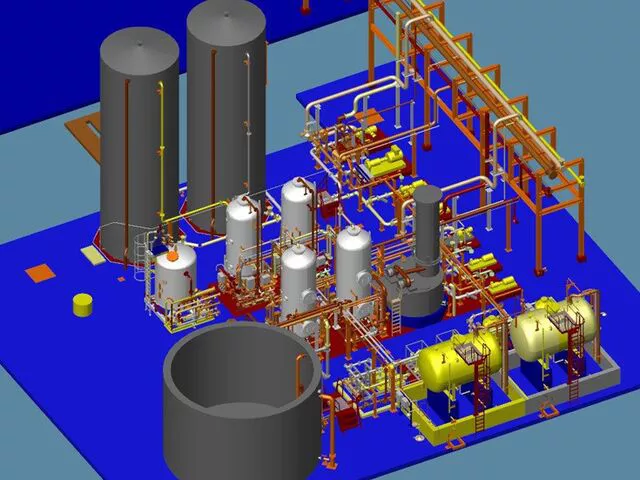

Ovivo’s Ion Exchange systems are incredibly versatile and can be used as a solution for a wide variety of industrial applications where demineralised water is required. We can supply ion exchange as an Ovivo pre-engineered and packaged plant or custom designed to your specifications. Ovivo also offer additional process steps such as suspended solids removal and degasification.

Ovivo Ion Exchange solutions have a range of benefits that put this product ahead of the competition, such as:

- Optimised processes designed to match any feed water conditions

- Uniform flow distribution to minimise chemical use and wastewater production

- Robust proven design, maximising plant uptime

- Fully automated for operation on unoccupied sites

- Compact footprint

Demineralisation Using Ion Exchange

Ion Exchange can be used in a variety of applications to remove specific ions from a water source or remove all the dissolved minerals and salts. Ion Exchange resins work by exchanging dissolved minerals for other ions in a reversible reaction.

In the case of a water softener, calcium and magnesium are exchanged for sodium ions but none of the anions are removed. When sodium chloride (brine) is passed over the resin this removes the calcium and magnesium from the resin replacing it with sodium. The cycle is then repeated on a continuous basis.

In a demineralisation plant all the cations are changed for hydrogen and all the anions for hydroxyl ions. Regeneration of the resins is then completed with acid passing through the cation column and caustic passing through the anion column. The plant is then rinsed to quality before being returned to service to produce more demineralised water.

Ion Exchange can also be used in drinking water applications, condensate polishing and downstream of membrane systems.

Ion Exchange demineralisation systems offer a range of technical features and benefits including:

- Compliance with international standards including EPRI and VGB requirements as well as IRDS for the semiconductor industry

- Treating a wide range of flows and pressures to meet site specific conditions

- Modular skidded design or mobile containerised units

- inCNTRL™ enabled to allow remote digital monitoring and diagnostics from mobile phone, tablet or PC

Our Ovivo team works closely with all partners to assist with their nitrate removal needs by providing:

- Feed studies

- Life cycle cost analysis

- Full design build support

- Process optimisation

- Refurbishments and upgrades