MOVEX™

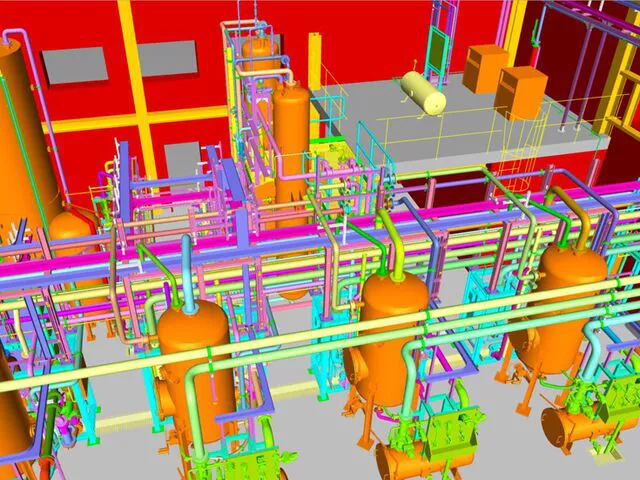

Movex is used to regenerate mixed beds externally within the ion-exchange system. The system is typically used on demineralisation and condensate polishing plants that have multiple large service vessels and a central resin regeneration facility.

Typically used on demineralisation and condensate polishing plants, Movex is available in various configurations, depending on the water treatment requirements and the amount of space available: from single vessel design to a multiple vessel arrangement.

Contact an ExpertMovex is suitable for use in steam boiler condensate treatment and other applications where high-quality water is required.

External resin regeneration is key to good quality water production, ensuring chemicals do not enter the process stream during resin regeneration. Movex is a simple and cost-effective mixed bed external regeneration technology that offers flexible and efficient resin regeneration. Movex is typically used where the ion exchange resins are of fixed ratio and volume. It also removes suspended solids that have been trapped in the resin during service, ensuring that the treated water meets the required quality standards.

High quality resin regeneration

External regeneration of resins has the advantage of very low cross-contamination of the ion exchange resins. By regenerating the resin externally, the physical separation of the operating and chemical handling systems eliminates the risk of chemicals entering the condensate circuit. One central external regeneration unit can serve different operating mixed bed vessels.

Movex offers a range of benefits, such as:

- Consistent treated water quality

- Reduced risk of chemicals contaminating product water

- Proven robust design

- Fully automated operation

- Compact footprint

Downloadable Resources

Movex External Resin Separation & Regeneration

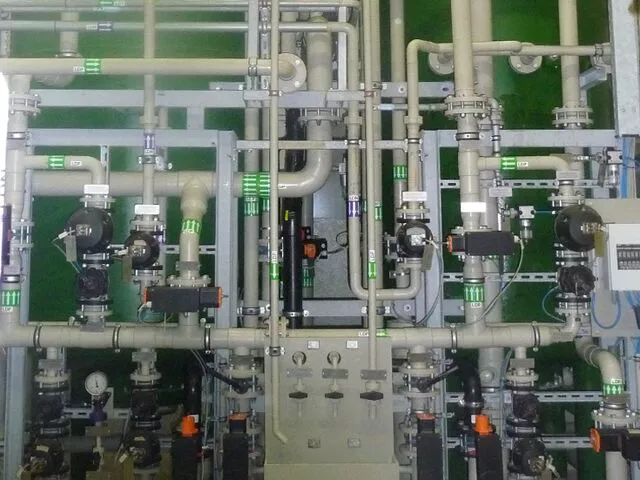

The Movex module consists of a regeneration vessel along with the associated pipe work, valves, controls and instrumentation. Resin from the mixed bed service vessel is transferred, using water, to the Movex regeneration vessel. An upward flow of water separates the resins with the cation resin accumulating at the base of the vessel and the anion resin migrating above. The cation resin at the base is then regenerated with acid and the anion resin with caustic, before both resins are rinsed. Once rinsing is complete the resin is mixed ready for return to the service vessel.

Movex Technical Information

Movex offers a range of technical features and benefits for your plant including:

- Single vessel regeneration system that reduces costs

- Effective resin cleaning to remove solids trapped in the resin bed

- Flexible skidded designs

- Retrofitting to existing plants

- opsCTRL™ enabled to allow remote digital monitoring and diagnostics from mobile phone, tablet or PC

The Ovivo team works closely with all partners to assist with their resin regeneration needs by providing:

- Feed studies

- Life cycle cost analysis

- Full design build support

- Process optimisation

- Refurbishments and upgrades