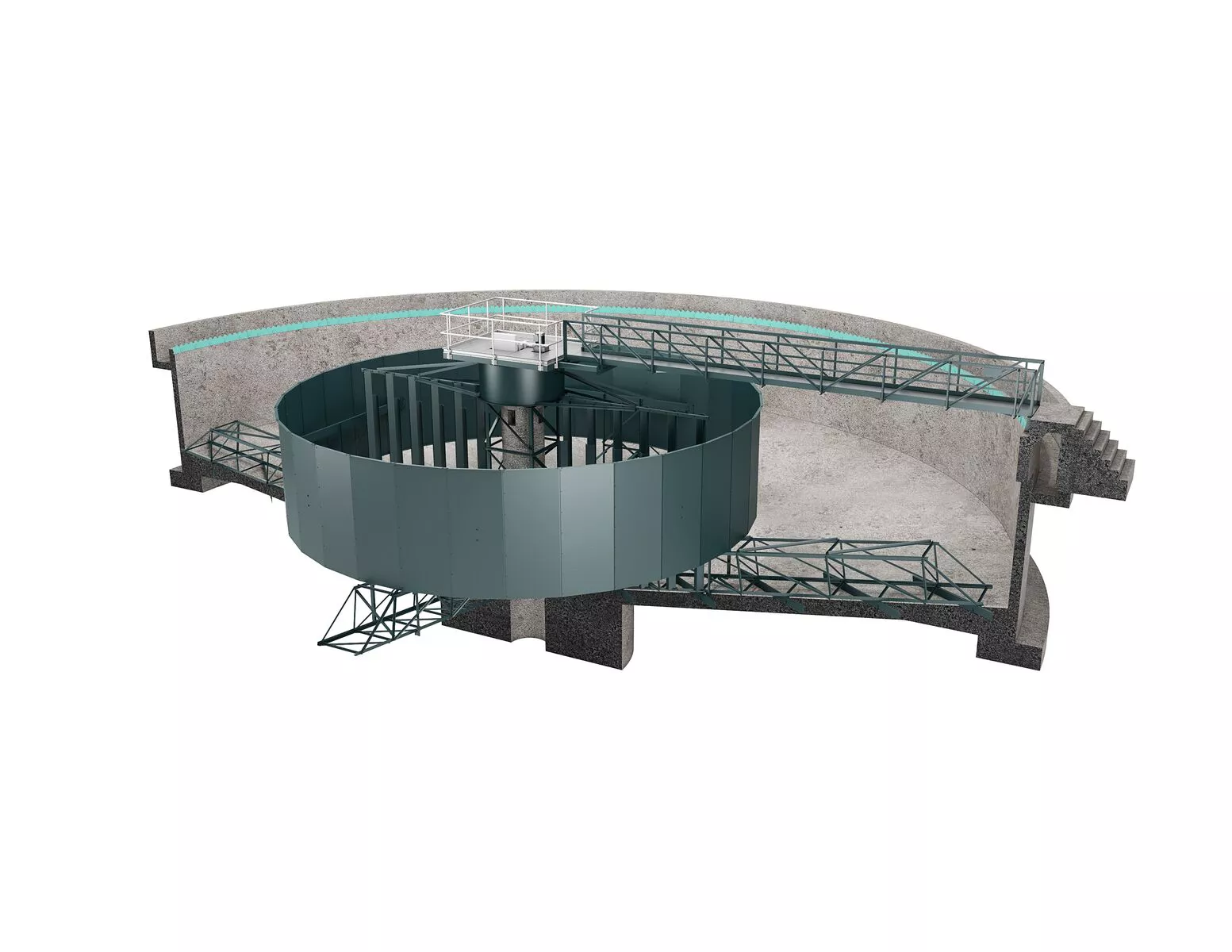

Clariflocculator®

Ovivo’s Clariflocculator provides flocculating, settling and solids removal in a single, dependable unit. Counter rotating paddles gently mix flocculant with feed streams to form floc that settles in the clarifier rather than in downstream filters.

Designed for use as a primary, secondary or polishing clarifier, the Clariflocculator reduces chemical consumption and costs for multiple tanks and piping. The dual counter rotating drives and paddles allow low tip speeds while utilising the full volume of the flocculating well, which promotes interparticle contact and agglomeration.

Contact an ExpertThe Clariflocculator is ideal to create bioflocculation or light to medium strength flocs without creating localised high velocities, potential floc destruction, or poor volume usage. Ovivo is one of the world’s leading providers of large-diameter slow rotating drives, with over a century of industry experience. We specialise in producing long-lasting durable solutions, with trouble-free installation and limited maintenance.

Our aftermarket support and customer service will ensure that your equipment continue to exceed expectations for its entire life. Some of the key features and benefits of our Clariflocculator include:Trouble free installation

- Long lasting durable design

- Dependable drive unit that offers low operation and maintenance

- Aftermarket support and customer service.

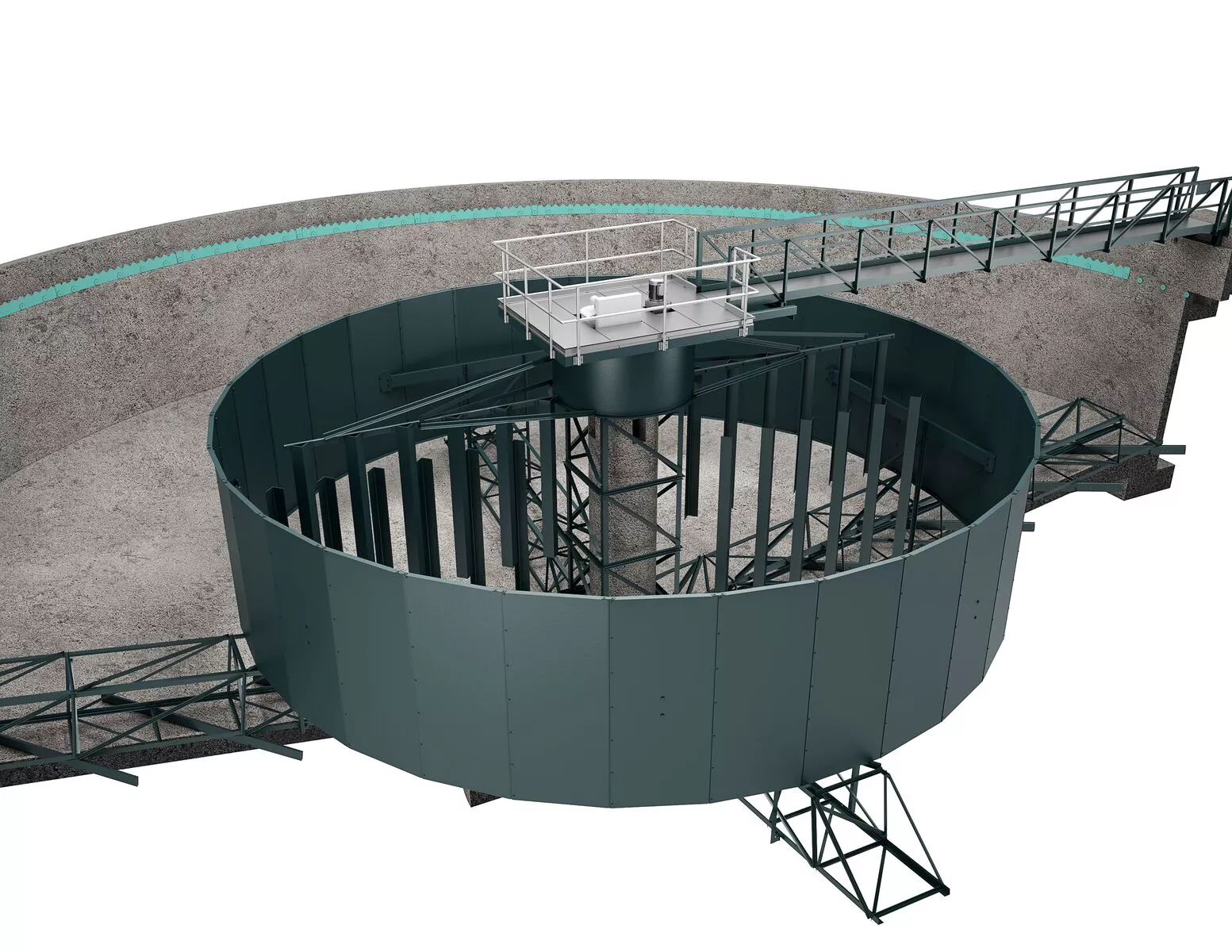

Specially designed counter rotating paddles

Ovivo’s flocculating clarifier features multiple, specially designed, counter rotating paddles that gently and thoroughly mix flocculant with feed streams. These paddles create eddies, or vortexing, on their trailing edge, which enables complete energy distribution without localized shear. The result is that the floc is mixed, rather than torn apart, allowing it to settle in the Clariflocculator, with reduced chemical consumption and expense, rather than on downstream filters. Rake arms driven by one of the dual drives move the settled sludge to the center of the unit to be removed through the sludge discharge pipes, either by gravity or pumps.