QuadraKleen® Filter

The QuadraKleen filter is a modular, four-cell granular media filter that delivers economical, continuous filtration in a variety of water treatment applications.

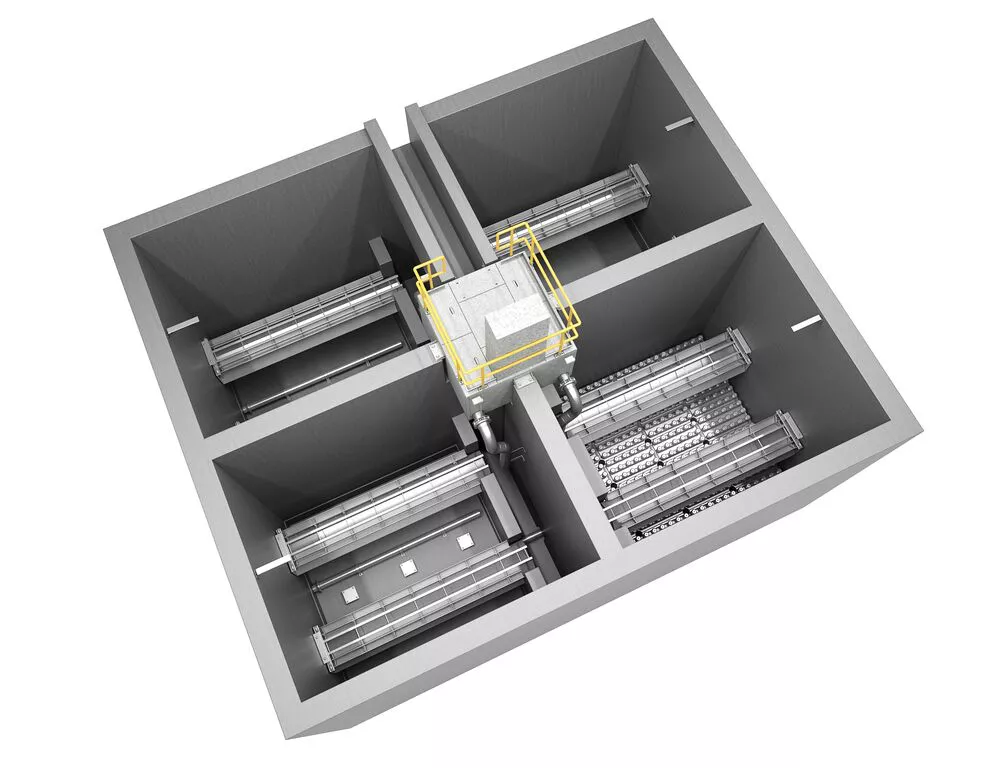

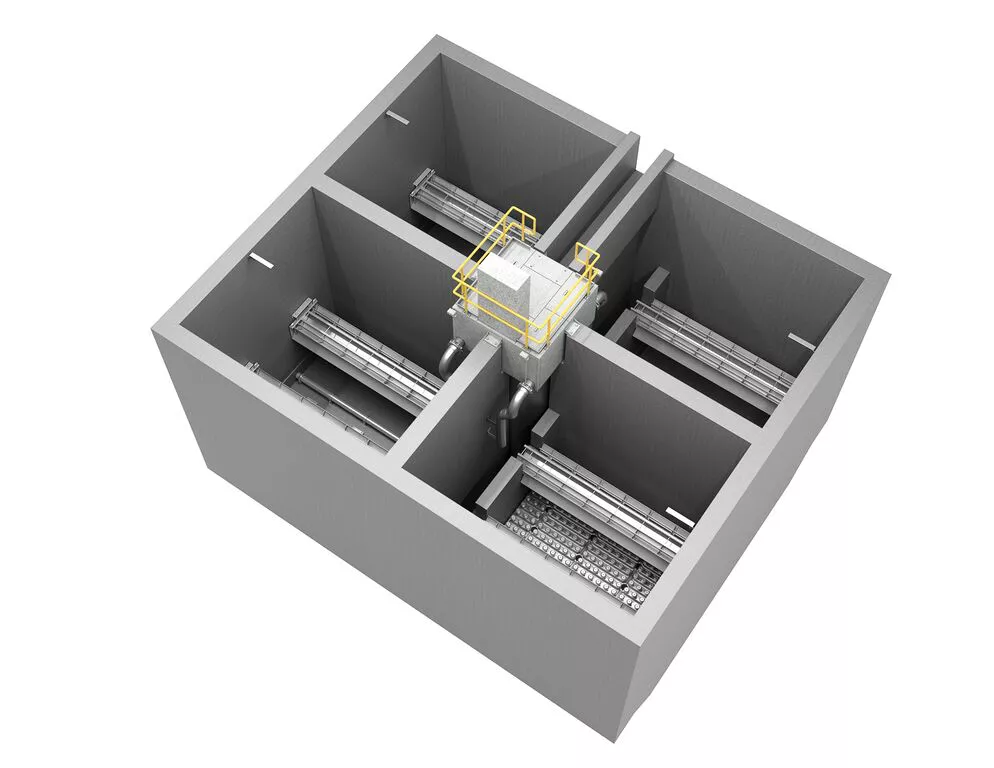

Each QuadraKleen filter consists of four filter cells clustered around common influent, effluent and backwash channels. This self-backwashing design allows individual cells to be backwashed using water produced by the other three cells, eliminating the need for water storage and minimizing filtration rate during backwash.

Contact an ExpertQuadraKleen filters are adaptable to a wide range of filtration requirements. The flexible basin geometry easily accommodates a variety of mono or dual media bed depths and media types, including sand, anthracite and granular activated carbon. Multiple QuadraKleen filters can be arranged around common influent/effluent channels, accommodating virtually any flow volume.

QuadraKleen filters have the following features and benefits:

- Simultaneous air scour and water backwash, with ScourGuard troughs, reduces duration of backwash cycles, wash water volumes, and media loss

- Self-backwashing, with no need for backwash supply storage, which can reduce costs

- Central access column simplifies maintenance

- Automated unit controlled from a central location

- Robust, stainless steel construction

Downloadable Resources

Each QuadraKleen module is designed around common channels for influent distribution, filtered water collection and backwash diversion. This economical solution eliminates costly pipe galleries for flow transport. An influent flume carries feed water to a central distribution box, where flow is equally split between all operating cells. Underdrain plenum channels convey filtrate from operating cells to the common effluent channel. Adjustable weirs in the effluent/backwash channel allow filtered water to overflow into a channel leading to a clear well or distribution system.

To backwash the filters, inlet valves control distribution among three operating cells. With levels rising in these three cells to provide adequate head, the waste valve opens in the offline filter cell, allowing draindown of that cell. Isolation valves allow filtered water from operating cells to flow as backwash supply to the cell being cleaned. Air-scour valves control flow to cells during simultaneous air-water backwash. The central waste drain and valve access column connects waste gullets in each cell where backwash waste is removed at a common waste drain. Following backwash, the now clean filter cell is put back into operation, and water levels in all cells return to normal.

The QuadraKleen Filter cell is entirely constructed from concrete. The stainless steel central valve access/waste drain column and splitter box are prefabricated and fully factory assembled. For underdrains, partners can choose from Ovivo’s FlexScour, Folded Plate, or CastKleen systems. The CastKleen® Filter Under Drain features monolithic slab construction and FlexKleen® Mark 3 flow control nozzles. The FlexScour and folded plate underdrains feature all stainless construction, providing ease of installation and robust operation. Optional ScourGuard™ wash water collection troughs protect against media loss during simultaneous air and water backwash, and reduce backwash waste volumes.

- The maximum filtration rate of each filter is 5.0 gpm/sf, translating to 15 gpm/sf with one filter in backwash

- Option to construct and operate multiple QuadraKleen filter systems together – operating a total of 8 cells together is common

- Ovivo’s stainless steel folded plate and FlexScour underdrains can be used with QuadraKleen filters