CastKleen® Underdrain

CastKleen Underdrain is a cast-in-place media filter underdrain that supports filter media, collects filtered water, and evenly distributes backwash supply water and air. This efficient filter can reduce waste and lower operating and management costs.

By combining a rapid fit floor-forming system with the flow management of Flexkleen™ nozzles, Castkleen offers substantial savings over other granular media filters in installation time, maintenance and improved media scour.

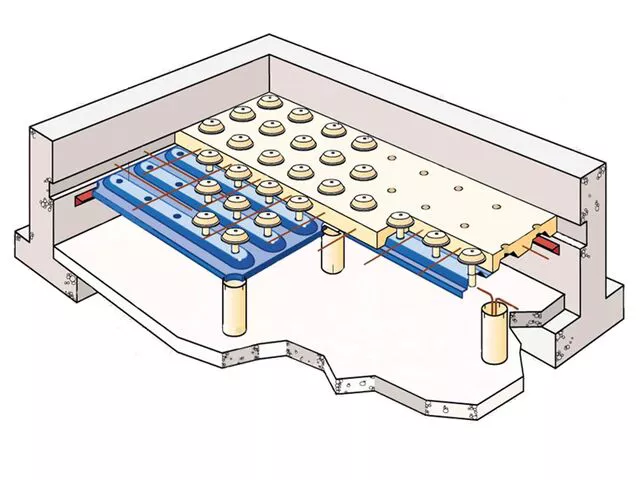

Contact an ExpertWith the Ovivo Castkleen Underdrain, the media is rapidly cleaned, using less water and with uniform distribution. The Castkleen Underdrain system utilises a concrete floor with reinforcing bars and Flexkleen Nozzles. The spacing of the nozzles, design of the multiple slots distributing the air and/or water, ease of adjustment for level, and the headloss generated through the nozzle, ensures uniform distribution and uniform cleaning of the filter media.

During operation, backwash water and scouring air flows are evenly distributed with FlexKleen nozzles. A fine comb of reverse wedge slots at the outer rim of each nozzle ensures consistent media cleaning and maximum filter throughput. The precision molded slots impose a uniform headloss and prevent media loss. Filter beds can be placed directly over the nozzles without a gravel support later, allowing maximum utilization of available head and reducing construction and maintenance expense.

The CastKleen Underdrain has the following additional features and benefits:

- Non-corroding components

- Monolithic structure

- Evenly distributed backwash and air scouring air flows

- Convenient and easy access to filter plenum

- Metric size underdrain panels for international projects

Downloadable Resources

For an air scour backwash to be effective, air must be evenly distributed throughout the media bed. Inconsistent cleaning leads to uneven filtration flow, the need for more frequent backwashing and declining filter throughput. The key to uniform air distribution is the careful placement of all air intake ports at the same elevation. In most underdrain systems, this is accomplished by a laborious process of floor leveling. The CastKleen Underdrain takes a different approach, without the need for expensive floor leveling or finishing.

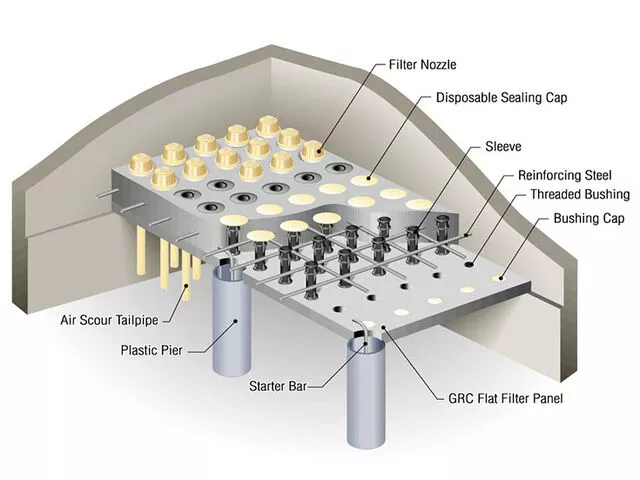

Ovivo uses a flow control nozzle that has been designed specifically for air scour applications and features an adjustable sleeve and tailpipe assembly. A fixed insert is locked into the floor panels with a snap ring, and is then encased within the concrete floor slab. The sleeve and tailpipe then slide vertically into the insert, and are held at the selected elevation by a tongue-and-groove locking arrangement. With the nozzle removed, a turn of the wrist unlocks, repositions and re-secures the tailpipe. Tailpipe elevation can now be achieved quickly and independently of floor grades, ensuring uniform media cleaning without the time and expense spent on floor leveling.

Using standard concrete construction techniques, cast-in-place CastKleen Underdrains are installed using snap-together components and cast-in-place installation techniques, which allow rapid, simplified assembly.

All floor forms and nozzle components are molded or vacuum formed from durable ABS plastic and are NSF certified. Construction is quick and simple and uses standard construction techniques. Time-consuming placement and grouting of pre-cast underdrain sections is eliminated. Access to the final filter plenum is convenient with a pier spacing of 2 ft by 4 ft (0.6 m by 1.2 m).