Flexscour® Underdrain

Ovivo’s Flexscour Underdrain provides a durable, corrosion‐resistant system for collecting filtered effluent and accurately metering uniform air and water backwash flows.

Innovative design features eliminate the two flow problems that have plagued other combined air and water cleaning systems: improper sizing of variable diameter orifices and media displacement by surging or irregular flows.

Contact an ExpertThe Flexscour Underdrain was originally developed as a retrofit system that would be sufficiently flexible to accommodate any existing pipework and tank arrangements without compromising efficient flow management. The same qualities have come to be make Flexscour a reliable underdrain for new water treatment plants.

Flexscour underdrains do not require false floors – they are an anchored system, not a grouted system. This ensures rapid, straightforward installation, ideal for rehabilitating older filters.

The Flexscour Underdrain has the additional features and benefits:

- Uniform cleaning achieves peak filter performance

- Rapid, straightforward installation (ideal for retrofits) reduces installation cost

- Allows greater depth of filter media, to meet stringent effluent quality requirement

Most header and lateral underdrains attempt to regulate backwash flow with variably sized orifices. However, traditional hydraulic models have proven inadequate for accurate sizing in areas of higher header flow velocity. The Flexscour Underdrain designers conducted exhaustive tests to gain a better understanding of the relation between crossflow velocity and turning resistance. These tests yielded a superior set of orifice sizing guidelines and an unequaled level of backwash uniformity.

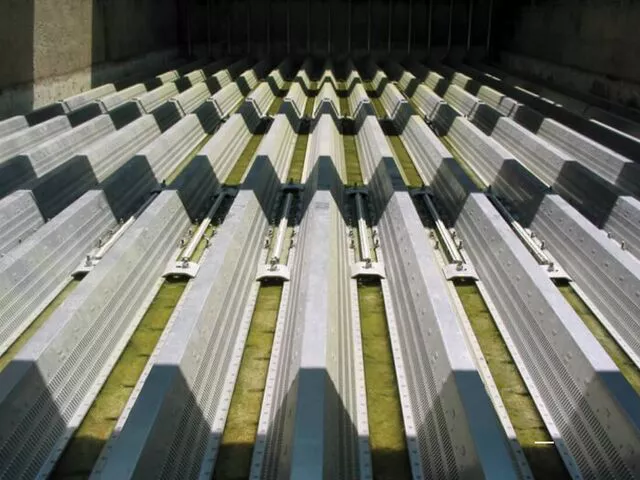

Typically, air is supplied from an overhead steel pipe while filtrate and backwash water flow through a concrete floor channel and primary orifices in lateral baseplates. A variety of feed and drainage arrangements are possible, depending on existing basin layout, with distribution orifices specifically sized for each application to ensure flow equalization. Lateral orifices are covered by stainless steel shields. The entire assembly is fastened to the filter floor with stainless steel anchor bolts.

The Flexscour Underdrain eliminates the surging wave action commonly responsible for media migration in combined air and water backwash systems. By partitioning lateral ducts into separate channels for air and water, the tendency of uneven pneumatic pressures to create reciprocating waves in header/lateral underdrains has been eliminated. Air distribution is uninterrupted, allowing vigorous, uniform cleaning with no media displacement. Where simultaneous air and water backwashing can be used, effective media cleaning can be accomplished with a fraction of the water required in alternating flow arrangements.

The Flexscour Underdrain has the following technical specifications:

- For simultaneous air-water backwash, the air rate is 3.0 scfm/sf and the water rate is 8 gpm/sf

- Scourguard™ backwash trough for media retention

What is the opening in the D90 Media retaining panels?

- D90 media retaining panel openings are 0.36 mm

- D90 panels are removeable and secured and sealed to the underdrain sloped sides with stainless steel machine screws and a neoprene gasket

- The low laterals (5 in height) allow for extra filter media depth, meeting today’s most stringent effluent quality standards, and clearance for air-scour bed expansion without raising the launder elevation

- Flexscour underdrains feature lateral ducts constructed of 18 ga. Stainless steel, axially partitioned into upper and lower channels for air and water