Brackett Green® Debris Filter

The Brackett Green Debris Filter is a fully automated, 24-hour, debris collection and removal solution that prevents macro fouling of heat exchangers, condensers, and other critical downstream equipment.

This system provides unsurpassed reliability with minimal maintenance and low operating costs. It features automatic self-cleaning without interrupting flow and can comply with all nuclear codes, or industrial codes as standard.

Contact an ExpertThe Brackett Green Debris Filter achieves unsurpassed debris removal with minimal water discharge. This fully customisable system has a range of features and benefits that place it ahead of the competition, such as:

- Designed to maintain operability during and after high-load applications, such as extreme debris influxes or seismic events

- Does not require an external pump or external water source for flushing

- Performs a complete backwash cleaning cycle without interruption to filter flow

- Vast range of mesh material options to suit a range of applications

Customisable designs and orientations to suit a range of applications

Our team of highly skilled engineers will select the optimal unit to suit the hydraulic requirements of your application and ensure that the highest efficiency and reliability are maintained, reducing operational costs and maintenance requirements. The Ovivo team works closely with our partners to understand their debris removal needs by providing support for:

- Customisable designs for optimal flow efficiency

- High differential applications

- Variable inlet and outlet orientations to suit site specific requirements

Zero carryover of debris

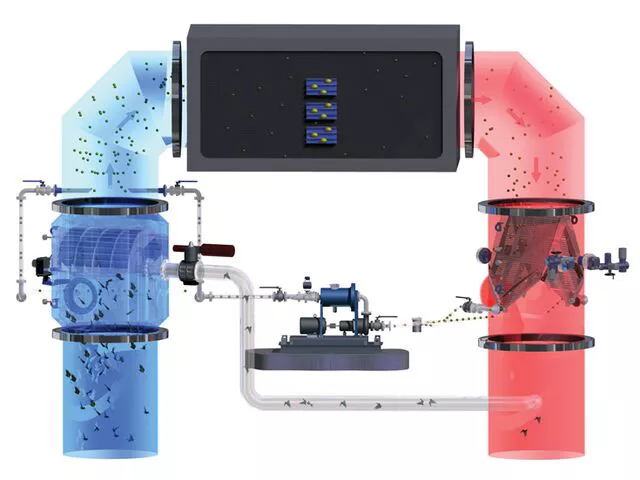

The Brackett Green Debris Filter consists of a vessel that can be mounted directly into an existing pipeline. The vessel contains a screening element and backwashing mechanism that can be operated manually or by pressure differential.

Water enters the inlet of the Brackett Green Debris Filter and passes through the screening element to the outlet. Any debris in excess of the screening aperture size is captured on the inside of the screening element. As debris accumulates, the differential pressure across the screen increases until a set point, where the cleaning cycle is initiated.

An actuated valve in the backwash line opens creating a positive line pressure. This causes a reversal of the flow, local to the backwash arm port, which lifts and coveys the debris out of the filter to an external discharge point. The backwash arm oscillates over the entire screening element surface until the differential pressure reduces to the clean condition parameters. The backwash arm then returns to the park position and the actuated valve is closed.

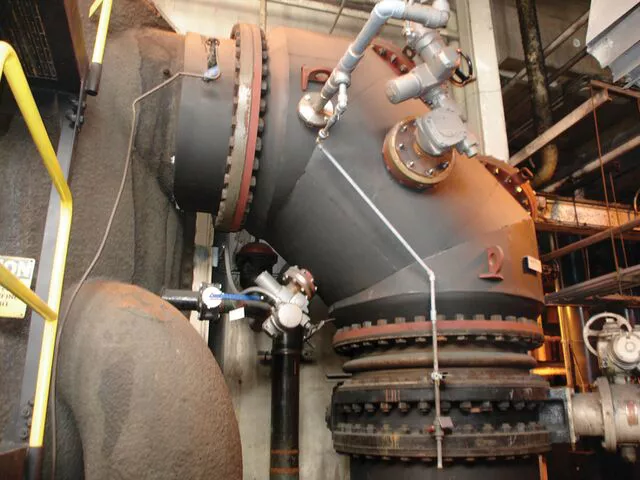

The Brackett Green Debris Filter has been successfully installed in hundreds of applications worldwide. This reliable system has been refined over years of experience, resulting in a reliable product with the following technical features and benefits:

- Flow capacities of 100,000 m3/hr+ (430,000 gal/min)

- Mesh aperture sizes ranging from 2.0 mm (0.08 in) and above

- Diameter from 300 mm (12 in) to 3,700 mm (144 in)

- Robust design capable of sustaining high differentials

- Fully customisable design and range of materials