Brackett Green® Non-Mechanical Screens

Brackett Green non-mechanical screens are simple, cost-effective solutions that capture debris and prevent fouling of downstream equipment in applications such as land drainage, nuclear and hydro power plants, chemical and petroleum plants, and drinking and wastewater plants.

Brackett Green Static Screens are removable and used to filter fine particles from process water; Fixed Bar Screens are non-removeable and ideal for processing larger water volumes and filtering larger particles.

Contact an ExpertBrackett Green Static Screens

This product is used in a variety of applications, including circulating cooling water and cooling tower blow down for power, chemical and petroleum plants. The Static Screen’s simple design makes it an ideal choice for upgrading existing systems using bolt-on guides, or for new plant designs using embedded guides. These screens can be installed as temporarily or permanent solutions.

- Simple and efficient design

- Inexpensive solution

- Perfect for cooling tower basins

- Variety of sizes and materials available

- Customisable mesh size, screen size and construction material to fit a range of water intake requirements and debris removal specifications

Brackett Green Fixed Bar Screens

Fixed Bar Screens can be designed to fit within guides or embedded into the concrete, or onto channel-mounted beams. They are permanently attached within the existing plant structure and cannot be removed. As their name suggests they consist of bars that filter larger-sized debris from the process water.

- Simple and efficient design

- Inexpensive solution

- Range of bar spacing sizes available (see technical information)

- Designed to withstand varying differential heads

- Simple retrofit into existing civil works

- Commonly fabricated of galvanized carbon steel or stainless steel, but other materials also available

- Customisable for a range of water intake requirements, debris removal specifications

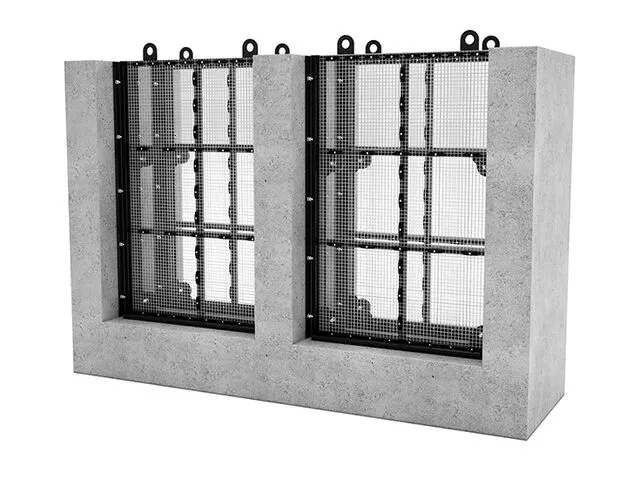

Brackett Green Static Screens

Two Brackett Green Static Screens are typically installed in series: a spare screen is lowered into place to continue screening while the upstream screen is removed and cleaned. Screens are framed wire mesh, and include a debris pan on the lower cross member for capturing loose debris as the screens are raised.

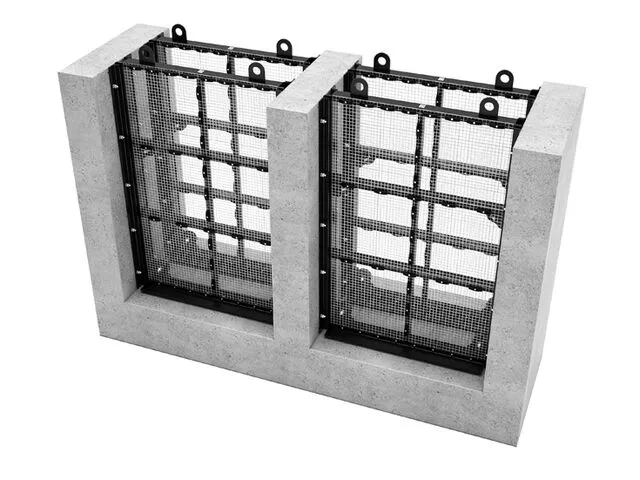

Brackett Green Fixed Bar Screens

Fixed Bar Screens are permanent installations where the supporting structure is rigidly attached to the civil works, requiring dewatering of the screen chamber for removal. These screens are designed to withstand a variety of differential heads and the bars can be arranged with bar spaces to accommodate any size or type of debris. A range of differing raking solutions can be provided for occasional, fully automatic or manual cleaning.

Fixed Bar Screens can be mechanically cleaned by one of a number of different raking type machines, or cleaned by hand using a rake, or by lifting and backwashing. The choice of cleaning method will depend on:

- Screen and channel size

- Debris quantity type

- Reliability and redundancy requirements

- Degree of automation required

Brackett Green Static Screen Specifications

Mesh sizes range from 5mm (3/16 inch) to 15mm (5/8 inch) square openings, and are usually electro-galvanized, 304 or 316 stainless steel. Frames are available in either epoxy coated carbon steel, 304L, or 316L stainless steel. Other materials are available on request.

Static screen frame size ranges in width from 0.5m (1.6 ft) to 5m (16.4 ft) and are custom designed for each site. Screen heights vary with each installation – they can extend to deck level, or can be used in conjunction with a lifting beam to automatically engage and disengage from the screen during raising and lowering operations.

Brackett Green Fixed Bar Screen aperture size

The type and size of the cleaning device is based on the physical size of bar screen, bar spacing, number of bar screens (in the case of a traversing raking screen), and any known risk of larger influxes of particular debris types e.g. jellyfish, kelp, sea grass.

For modern civil work intakes, the principal types of raking machine used are:

- Fixed head cable-hauled raking machine

- Traversing cable-hauled raking machine

- Bosker® raked bar screen

- Continuous chain raked bar screen (CCRB)

To determine bar screen size, the following data are required:

- Maximum design flow

- Minimum depth of water at design flow

- Bar spacing

- Any limits on channel dimensions

- Any customer specified limits on design velocity or headloss