EloVac®-P

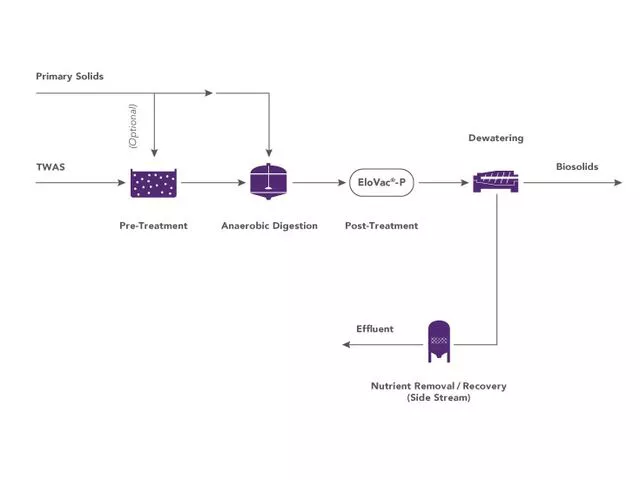

EloVac-P is a modular, plug-and-play phosphorus sequestration and struvite mitigation system that improves solids dewaterability and increases cake solid percentage. It provides effective nutrient removal, specifically phosphorus removal.

It’s vacuum-based, low energy operation, coupled with enhanced biogas and carbon dioxide capture, enables energy-positive operation and helps reduce a plant’s carbon footprint, while reducing polymer consumption.

Contact an ExpertEloVac-P is designed for sidestream treatment of solidstreams. It is a fully engineered, plug-and-play system that provides multiple benefits across wastewater treatment plants. In addition to phosphate management, benefits include:

- Reduced Phosphate by 80 to 95 percent in the return load to the head of the plant

- Improved dewatering by up to 5 percent

- Reduced polymer consumption by up to 20 percent

- Reduced downstream struvite scaling

- Low footprint and plug-and-play nature help reduce overall project costs

- Additional biogas capture leading to energy positive operation

- Reduced carbon footprint of plant by up to 25 percent

The EloVac-P works by continuously feeding sludge to the degassing reactor.

A vacuum degassing pump extracts the methane and carbon dioxide from the digested sludge. This raises the pH in the reactor and allows for controlled struvite precipitation, providing effective nutrient and phosphorus removal as well as struvite mitigation. Magnesium chloride is added to the digested sludge for this purpose. The resulting degassed sludge with precipitated struvite is then discharged for dewatering and biosolids production.

EloVac® is a registered trademark of ELIQUO Water Group GMBH