NITRASEP® Nitrate Removal

Nitrates occur naturally in the environment and in some locations, such as areas of intensive agriculture, nitrates can enter ground water sources at levels that are hazardous to health.

Ovivo offers a range of solutions that reduce nitrates to safe levels for use in drinking water supplies, including the innovative NITRASEP nitrate removal process. These compact, water and salt efficient units are designed to optimise operating costs and provide reliable operation.

Contact an ExpertNITRASEP provides sustainable industry-leading ion exchange technology for the removal of nitrate from drinking water sources. This highly efficient system is designed to reduce operating costs and minimise environmental impact.

Flexible nitrate removal solutions

The NITRASEP system is incredibly versatile and can be used as a solution for municipal, private, construction camp and industrial applications, where nitrate removal is required from clean water. NITRASEP can be supplied as a package plant or custom-built to client specifications.

NITRASEP has a range of benefits that put this product ahead of the competition, such as:

- Uniform flow distribution to minimise salt and wastewater production

- Robust proven design maximising availability

- Fully automated for operation at unoccupied sites

- Compact footprint with low headroom requirement

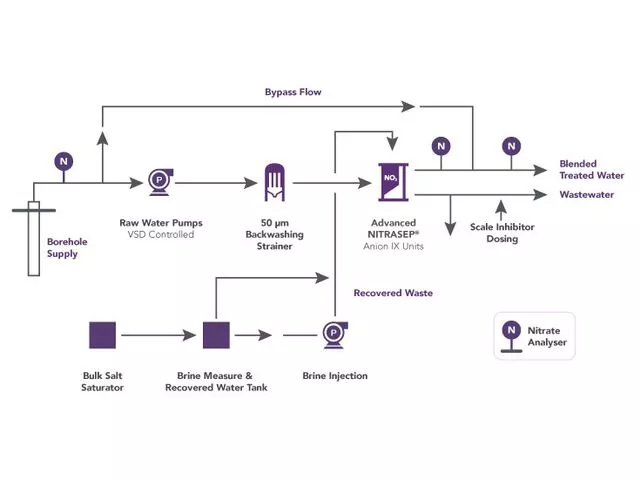

Only partial removal of nitrate is normally required to comply with drinking water standards. The Ovivo Nitrasep system monitors the incoming flow and nitrate concentration to calculate the flow that needs to be treated. This flow is then pumped using a variable speed drive pump through a backwashing strainer, where solids are removed before passing through a set of ion exchange vessels.

Inside the vessel is a nitrate selective ion exchange resin that is approved for use in drinking water applications. The plant is operated in a loading cycle where the water supply passes over the resin and the nitrate is removed and retained. When the vessel is fully loaded with nitrate a brine solution is used to regenerate the resin. This removes the nitrate and, after rinsing, allows the vessel to be returned to service.

NITRASEP reduces wastewater production and salt consumption by optimising flow distribution within the vessel, as well as the regeneration cycle, according to the specific site requirements.

inCTRL™ , supplied as standard with all Ovivo Nitrasep units, allows remote monitoring, Ovivo service engineer contact, storage of O&M manuals and predictive maintenance tracking.

Nitrasep offers a range of technical features and benefits including:

- Compliance with DWI and FDA requirements

- Compliance with European, US and WHO water quality standards

- Treating a wide range of flows and pressures to meet site-specific conditions

- Treated water typically <5 mg/l NO3 minimising treated flow

- Raw and treated water blended to meet local requirements (typically <50 mg/l NO3)

- inCTRL enabled to allow remote digital monitoring and diagnostics from a mobile phone, tablet or PC

- Modular skidded design or mobile containerised units

- Engineered with reliability and ease of operation at the forefront

Our Ovivo team works closely with all partners to assist with their nitrate removal needs by providing:

- Feed studies

- Life cycle cost analysis

- Full design build support

- Process optimisation

- Refurbishments and upgrades