Detritor® Grit Removal

Grit removal is critical for efficient plant operation. Wastewater containing grit can increase operating costs, downtime and maintenance resources, as well as leading to unnecessary maintenance and permit compliance issues.

The Detritor Grit Removal system is a cross flow grit system that utilises a collector arm to move settled grit into a vessel for collection. It provides reliable removal of abrasive, heavy and insoluble inorganic grit, which can accumulate in municipal wastewater treatment plants.

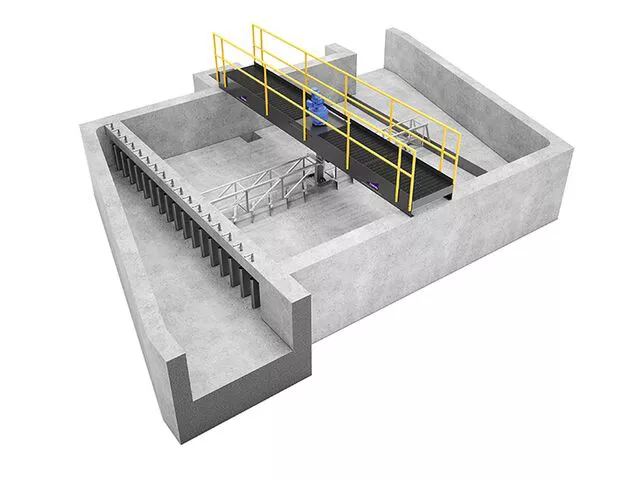

Contact an ExpertThe Detritor Grit Removal requires minimal excavation costs as only a very shallow tank is necessary. The system has a proven reputation for continuous operation with minimum maintenance and low power consumption and head loss. Ovivo has been selling Detritors for over 50 years, with many units lasting more than 45 years due to their durable construction.

Best removal efficiency

Studies that compare three different technologies (vortex, stacked structured vortex and Detritor) have shown that The Detritor Grit Removal system has the highest collection efficiency. This is largely due to the Detritor having the lowest surface overflow rate

Designed for square, shallow, concrete tanks with filled-in sloping corners, Ovivo’s Detritor consists of a rotating, center-driven rake mechanism mounted on a structural bridge which spans the collection basin. Sewage enters along one side of the tank through adjustable vertical gates which are set to provide uniform velocity across the entire width of the Detritor. After entering, the sewage flows in straight lines across the tank and flows over a weir with free.

discharge extending along the entire outlet side of the tank. All grit coarser than the desired mesh of separation (usually plus 65 or 100 mesh) settles to the floor of the Detritor.

The collecting mechanism consists of two structural steel arms that are attached to a vertical shaft and fitted with outward raking blades with scoops on the ends. As the rakes revolve, settled grit is plowed outward to the periphery where the end scoops collect and discharge it into a hopper at one side of the tank.

Detritors are available in sizes that range from 3 to 12 m (10 to 40 ft) in diameter. Designed on a hydraulic loading basis, Detritors can be sized to efficiently remove up to +150 mesh grit with a specific gravity of 2.65.