Brackett Green® CF100® Band Screens

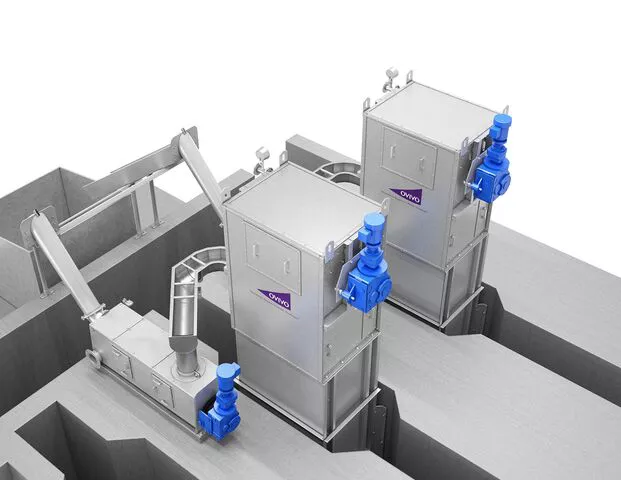

Highly refined through decades of experience, the Brackett Green CF100 range of screens can efficiently remove large volumes of debris and protect downstream equipment for wastewater and cooling water applications.

The Brackett Green CF100 travelling band screen collects, conveys and discharges debris directly into a deck mounted gulley. Incorporating a patented tapered-hole mesh design, it provides fully automated operation and 24-hour coverage.

Contact an ExpertIdeal for new or retrofitted wastewater and cooling water intakes

The Brackett Green CF100 Band Screen is supplied as a single fully assembled solution, enabling a rapid, risk-free installation.

The Ovivo team works closely with all partners to assist with their debris removal needs by providing:

- Feed studies

- Design optimisation (cost engineering)

- Life cycle cost analysis

Fully customisable for a range of water intake requirements

Brackett Green CF100 Band Screens are fully customisable and offer a range of benefits that put this product ahead of the competition, such as:

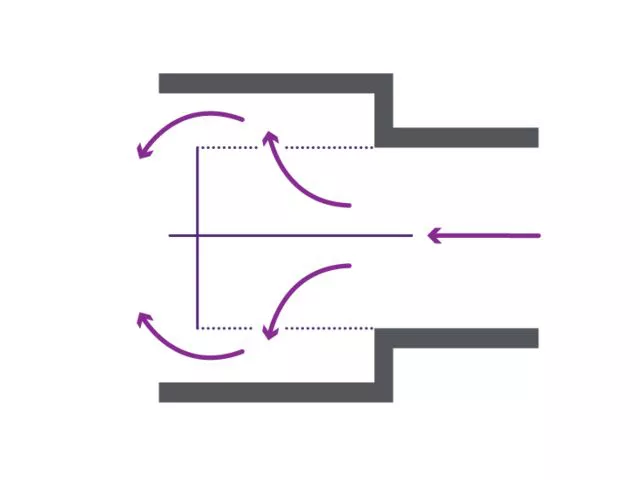

- Uniform centre flow distribution to eliminate carryover

- Patented Propapanel® technology to eliminate hairpining and blinding

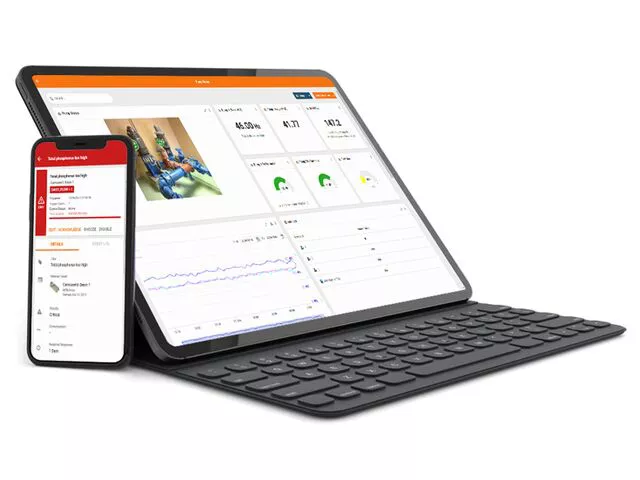

- opsCTRL™ enabled to allow remote digital monitoring and diagnostics from mobile phone, tablet or PC

- Low noise operation for urban sites.

Downloadable Resources

Eliminating debris bypass

The water enters the center of the screen, and then flows through the mesh panels to the outside of the screen. The debris is collected on the inside of the patented Propapanel and is then lifted above deck level by a shaft mounted electric drive unit, where it is washed directly into the gulley by wash-water jets. This flow pattern ensures the ‘dirty’ side of the mesh is never exposed to the ‘clean’ flow, and therefore prevents debris carryover.

The mesh guides and head frame assembly (complete with drive gear) are supported by a fabricated steel frame, which is assembled in sections and is freestanding in the screen chamber. This style of frame construction allows for removal of the screen in sections for major maintenance, reducing space requirements for headroom.

Monitor your plants activities from wherever you are

opsCTRL™ can be supplied with all CF100 Band Screens, enabling remote monitoring, Ovivo service engineer contact, storage of O&M manuals and predictive maintenance tracking.

The CF100 has been successfully installed in hundreds of applications worldwide. The design has been refined over the years, resulting in a patented product that includes several key partner benefits:

- Pre-engineered options or customised to partner specifications.

- Mesh aperture size from 2 to 10 mm.

- Fully customisable for depths from 0.7 to 9.7 m (2 ft 4 in to 29 ft 10 in)

- Capability to handle a wide range of flow rates

- Stainless Steel 304L frame with Polypropylene panels (alternatives materials available)