PHOSPAQ™

PHOSPAQ is a system designed for sidestream treatment, with a focus on removing phosphorus, through controlled struvite precipitation.

The PHOSPAQ process is able to handle complex streams and offers options for dewatering and utilising the produced biosolids. Additionally, it helps prevent struvite buildup, promoting compliance and reducing maintenance needs.

Contact an ExpertPHOSPAQ is a compact and highly efficient system that helps optimise phosphate management across the plant while also offering the flexibility of phosphorus recovery. The process also acts as an excellent pretreatment step ahead of deammonification, ensuring the overall process train optimisation with minimal operating and maintenance (O&M) requirements.

PHOSPAQ has numerous features and benefits, such as:

- Flexibility of design for phosphorus removal or recovery

- Low O&M Costs

- Simple operation with compact construction

- Enhanced struvite precipitation with free BOD and sulphide removal

- Longest experience with large reference base

Downloadable Resources

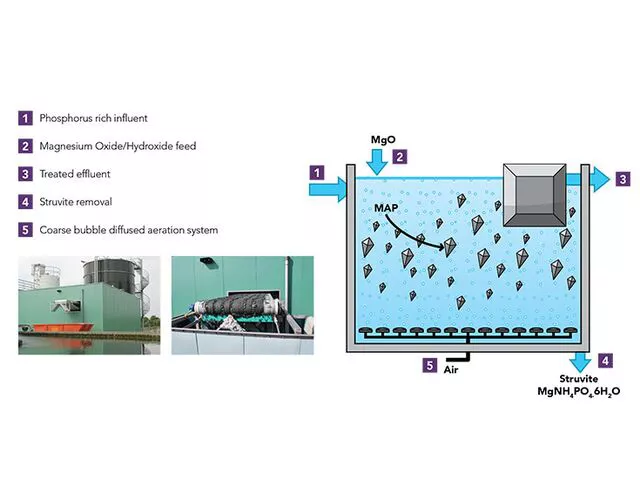

The PHOSPAQ process takes place in an aerated tank and works by continuously and completely mixing nitrogen and phosphorus present in the concentrated sidestream with magnesium oxide or magnesium hydroxide to form magnesium ammonium phosphate (MAP), otherwise known as struvite. The continuous aeration helps in stripping out the carbon dioxide, increasing the pH and crystallisation process of struvite.

The produced struvite can either be dewatered, mixed with biosolids and disposed of, or further processed for recovery as a fertiliser product.

PHOSPAQ™ is a registered trademark of Paques BV