Carrousel® System

The Carrousel System is a biological treatment process that removes biochemical oxygen demand (BOD), total nitrogen (TN) and total phosphorus (TP) to meet the most stringent effluent guidelines in the industry.

This activated sludge system achieves low TN and TP levels in domestic wastewater without chemical addition. Ovivo provides high-performance surface aerators and reliable mixers in the Carrousel System to deliver flexible biological nutrient removal (BNR) at a variety of operating conditions.

Contact an ExpertOvivo has been designing and installing Carrousel Systems for over half a century and has over 800 installations worldwide. We are consistently working to develop innovative and efficient processes, equipment and process control strategies to enhance the Carrousel System. These efforts set the standard in advanced oxidation ditch technology and establish a level of excellence in performance and energy efficiency in the industry.

How is the Carrousel System different?

The Carrousel System uses the unique Excell® Aerator, a high-efficiency surface impeller connected to a floor-scouring lower impeller. This impeller combination provides superior aeration turndown capabilities while still mixing the basin efficiently. This enables plants to operate from full aeration power down to 10 to 20 percent of the nameplate power to efficiently treat low loads and avoid over aeration in the biological system. The Excell Aerator delivers the best dissolved-oxygen control, mixing efficiency and energy savings on the market.

When total nitrogen removal is required, Carrousel denitIR® Systems with anoxic zones are recommended. These systems include Ovivo’s patented EliminatIR™ gate, which is an innovative automated control gate placed in a channel that connects the aerobic zone to the anoxic zone. This gate fine-tunes the nitrate recycle flow to the anoxic zone and eliminates the need for a Mixed Liquor Suspended Solids (MLSS) pump. A modified version of this gate, the divertIR™ gate, alternates the delivery of influent flow to different BNR zones in the specialised Carrousel AlternatIR™ System for biological phosphorus removal.

Ovivo’s advanced Oculus™ System, for process control, has evolved over the last decade to enhance and optimise the Carrousel System. It combines the customised control system with carefully selected process instruments to save power and maximise nutrient removal in the Carrousel System. Ovivo provides recommended pre-sets for each plant’s start-up and instructs operators in a variety of easy-access operating strategies that make it simple and low-risk to fine-tune their operation as plant loading increases over time. Remote monitoring by Ovivo process engineers is also available with the Oculus System to help and support operators.

Downloadable Resources

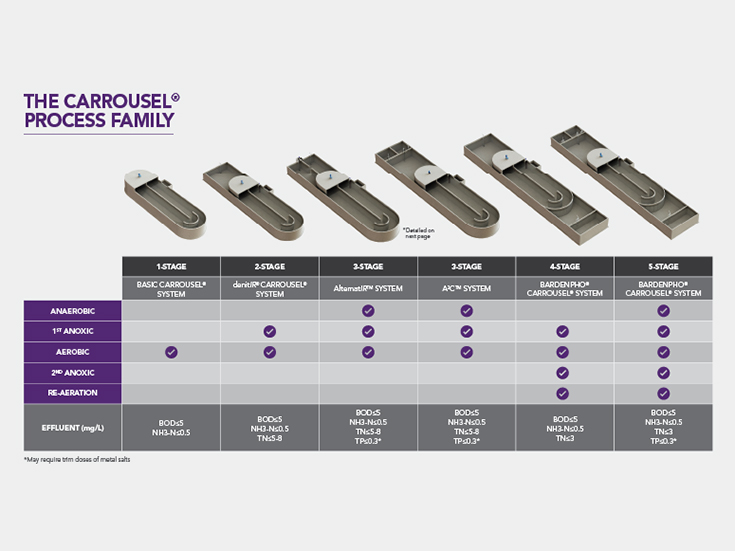

Multiple stages for complete treatment

The Carrousel System begins with the aerobic stage. The Excell Aerator introduces oxygen into the mixed liquor to meet the oxygen demand in the system. Oxygen allows organisms to thrive and consume BOD and oxidise ammonia. This stage is well mixed and can operate at a wide range of aerator horsepower.

The second stage is the anoxic stage, provided for nitrate removal. This stage is located upstream of the aerobic stage and is devoid of dissolved oxygen. The natural biological process that occurs here, denitrification, creates nitrogen gas from nitrate. This gas is released into the atmosphere (which is already 78 percent nitrogen gas) as flow reaches the aerobic stage.

The third stage is the anaerobic stage. In this area, devoid of dissolved oxygen and nitrate, organisms responsible for phosphorus removal are developed.

The fourth and fifth stages provide nitrate removal to very low levels (second anoxic stage) and subsequent removal of nitrogen gas (reaeration stage), respectively.

Six different flow sheets, including Bardenpho® systems, are currently available. All of them have the unique free internal recycle to maximise TN removal. Our popular Carrousel denitIR system targets BOD and total nitrogen removal (as low as 3 mg/l TN). Also available is the flexible Carrousel AlternatIR™ system which removes BOD, nitrogen and phosphorus in a two-stage system. The more traditional A2C™ Carrousel system has dedicated anaerobic zones for biological phosphorus removal.

Ovivo provides extensive process evaluation for unique process requirements, such as:

- Adding new stages to existing single-stage Carrousel Systems for stricter nutrient limits

- Replacing existing Carrousel System aerators with higher-horsepower aerators for greater capacity (“wet” retrofits are often possible)

- Adding volume to existing Carrousel Systems using higher walls or extended tank lengths when greater capacity is required

- Wrapping Carrousel Systems around clarifiers

- Retrofitting concentric-ring and sloped-wall oxidation ditches with Carrousel System equipment

Ovivo sells the Carrousel® system under a license agreement. Carrousel® is a registered trademark of Royal HaskoningDHV